Medium voltage

GABRO underground MV/LV container stations in concrete enclosure

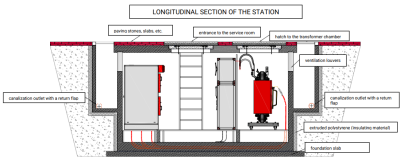

The station is designed for urban areas with dense buildings, parking lots, plazas and places where there are difficulties with the installation of a traditional station. When locating the station housing, distances between buildings and off-road equipment should be maintained, as well as distances from the boundaries of the plot and from buildings on neighboring building lots.

Implementation

- The prefabricated transformer station is a reinforced concrete structure in which the following functional areas can be separated: MV switchgear; LV switchgear; transformer; telemechanics and automation.

- The station has a reinforced concrete floor with process passageways for the entry and exit of cables between the MV switchgear and the transformer. Underneath the transformer is a sealed oil sump, which is used to collect oil from the transformer in case of a leak or failure.

- In the side walls of the enclosure are designed sealed cable passages for the introduction and exit of cables to the MV switchgear and LV switchgear. The switchgear room is separated from the transformer by a perforated steel mesh partition.

- Heat dissipation from the equipment is provided by gravity ventilation through the use of two sidewalk ventilation grilles at the top of the station housing.

- Sidewalk ventilation grilles are made to protect the footwear of passersby and at the same time are resistant to external loads. The housing hatch is made so that technological equipment can be replaced. In the large manhole is made a hatch for service. Manholes are covered with granite elements of the sidewalk. All metal elements exposed to weather conditions are hot-dip galvanized.

- The inner surface of the walls is painted with white emulsion paint, while the outer surface is covered with heavy waterproofing compound insulation to eliminate the possibility of water entering the station.

- The enclosure was designed taking into account an additional load of 5 kN/m2 as a substitute load of the overrun for a light truck with load or heavy truck without load according to PN-88/B-02014.

Product quality

- The quality of the product is monitored at every stage of production in compliance with EN ISO 9001:2009. We provide a basic 24-month warranty with the possibility of extension upon request. The station is made of the highest quality materials and tested and certified equipment.

- During the warranty and guarantee period, the manufacturer is liable for defects and damage caused by faulty design, use of improper materials or improper workmanship. It is possible to extend the warranty at the request of the customer for the station and apparatus.

Equipment

- The equipment of the station is selected each time according to the needs of the customer and the functional requirements that the station must meet.

- Walls – vibrated reinforced concrete class C30/37, wall thickness 14 cm.

- Bottom plate – reinforced vibrated concrete of class C30/37, slab thickness 25 cm.

- Floor slab – reinforced vibrated concrete of class C30/37, slab thickness 20 cm.

- Ventilation louvers – aluminum covered with paint in color according to RAL palette.

- External ventilation grilles (bridges) – galvanized steel.

- Manhole (cover)– hot-dip galvanized steel.

Frequently asked questions

What is your delivery time?

Standard delivery time is approximately 6-8 weeks depending on the order. Please contact us to arrange a more detailed delivery date.

What effects do your charging stations have?

We offer an extensive range of products, encompassing both AC and DC EV chargers featuring diverse equipment configurations and power outputs. The power spectrum of our EV chargers includes:

- AC 3.7-43 kW

- DC 40-480 kW

Who installs charging stations?

Charging stations are only installed by Swedish certified electricians.

How fast do your stations charge?

The fastest DC chargers can charge a car in up to half an hour. Charging time for electric vehicles depends on:

- EV charger power

- battery capacity

- the power of the converter installed in the car.

Which station is best for private use?

The best choice for private use are small stations such as:

- EVB E-wall - mounted in the wall not only makes it much easier to use, but also blends almost seamlessly into the façade and improves its aesthetics.

- EVB Wallbox 2M AC - it can be hung on the wall in the garage, thanks to which it takes up little space and can charge two cars at the same time. Charging point power up to 22 kW.

How is the advertising content on EVB Adverts charging stations managed?

Advertising content on EVB Advert chargers is managed using the Digital Signage Android Player. It is an extremely functional software for remote management of content on the monitor. The software allows you to manage content from any place with Internet access - just log in to the relevant website, upload videos, images, webpages, RSS feeds, remote content, divide the screen into any number of screen areas of any size and position, and much more. The big advantage of Central Stacks software is that the server is in the cloud, so the client does not need to install and maintain it on its side, and therefore the content of any connected media can be managed anywhere and on any device by logging into the server through a web browser.

Our billing model for Central Stacks licenses is also very simple and transparent, unlike many other systems on the market, since the annual license price already includes all the costs incurred by the customer for the system including server maintenance, etc., so at each stage of the project the customer knows exactly how much it will cost him to expand the DS network with additional installations.

How to settle accounts with charger users?

Our stations are equipped with a measurement and billing system, which enables quick settlement with the customer. Settlements are made via mobile applications, RFID cards or a payment terminal.

What is the difference between charging a car with AC and DC?

In the simplest terms, the key distinction lies in the charging speed of the vehicle. In the case of alternating current (AC), the EV is usually charged slower compared to direct current (DC), because the alternating current needs to be converted, and the charging speed depends on how much current the wallbox can supply and how much current the vehicle battery can handle. Charging with alternating current is the most popular method of charging electric vehicles and is widely used, among others, while charging at home.

DC charging, on the other hand, is a faster charging option often used in public places using chargers with higher power outputs. Unlike AC charging, DC charging delivers direct current to the vehicle battery without a conversion process. The type of charging station you should install depends entirely on your needs and specific requirements. In public areas such as parking lots, a combination of AC and DC charging can provide a pragmatic solution to meet the diverse needs and preferences of different guests.

Are you nationwide?

Yes, we provide installations throughout Sweden, as well as in Europe.

Contact us

We are a dynamic company that places a strong emphasis on technology and innovation. With extensive experience in electrical systems, power solutions, and control mechanisms, we are well-equipped to meet your needs.

Our mission is to provide you with the most sustainable, environmentally friendly, and efficient solutions available. Contact us and discover how we can help you achieve your goals.